The Production Process of Cosmetics - Skin Care Factory

Making cosmetics isn’t too complex, but doing it right takes precision. Every step must follow strict guidelines. If not, defective products might lead to recalls.

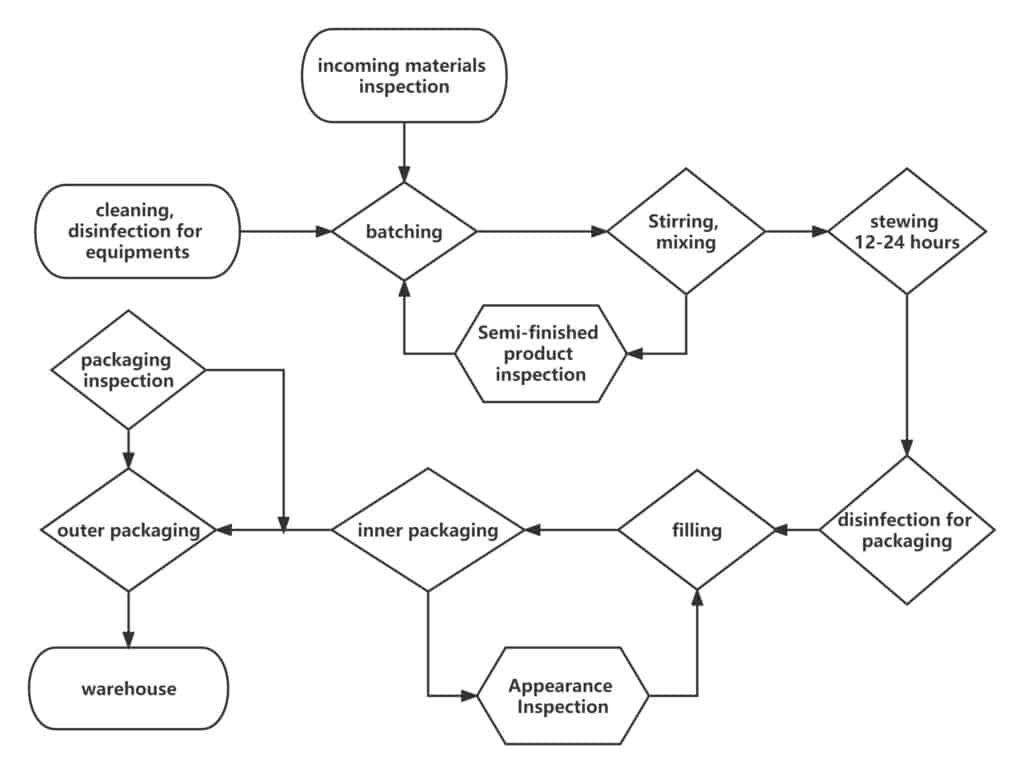

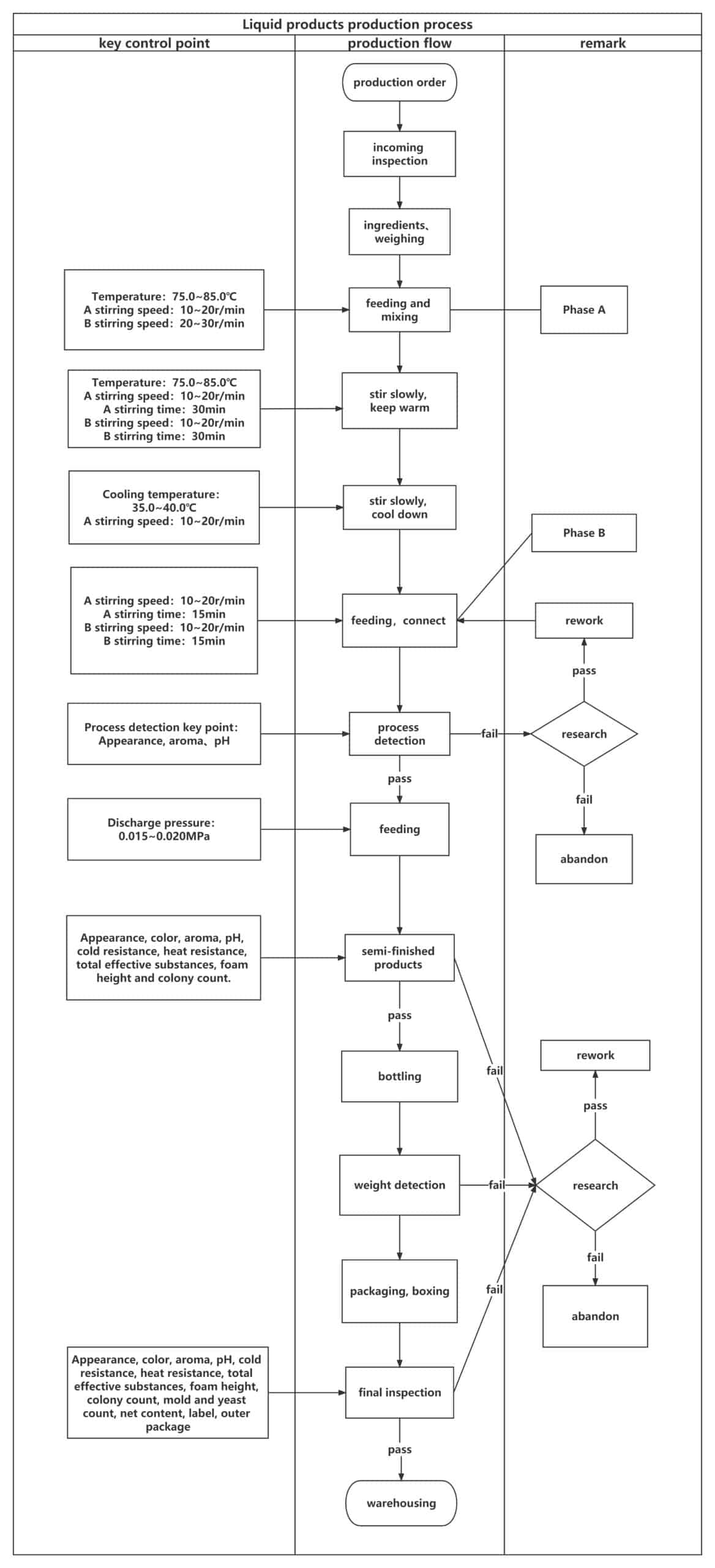

The production process has four main stages. Each stage must follow safety rules carefully.

Step 1: Preparing Materials

Cosmetics contain different raw materials. Knowing their physical and chemical properties is essential. The right percentage and order of mixing matter.

Some materials need special treatment before use. Some must be warmed in a heating room. Others must dissolve in a solvent before mixing. Water must be deionized to remove impurities. These steps take time but are necessary. Skipping instructions can cause production issues.

Measuring ingredients accurately is critical. The method and units of measurement must be precise.

Step 2: Mixing and Emulsification

Cosmetic products are either homogeneous mixtures or emulsions. Stirring ensures an even blend.

Water-soluble and oil-soluble materials must be mixed separately. Later, they combine through emulsification, high heat (60-75°C), and stirring.

The mixer plays a key role. Some cosmetics contain surfactants, which can trap air. To prevent bubbles, the liquid level should stay below the stirring paddle. Over-mixing must be avoided.

Step 3: Post-Mixing Processing

Before packaging, the mixture undergoes additional steps to improve stability and quality.

Homogenization: It refines the emulsion, making particles smaller and more uniform. This improves stability.

Exhaust: Stirring creates tiny bubbles. A vacuum device removes trapped gas.

Filtration: This removes solid impurities or unwanted particles that can affect the product’s appearance.

Stewing (Aging): The mixture rests for 12-24 hours. This stabilizes the formula and allows bubbles to escape naturally.

Step 4: Filling and Packaging

Filling and packaging are crucial. Mistakes here can ruin the entire process.

The filling volume must be precise. Capping, labeling, and boxing require careful attention. Packaging quality is just as important as product quality.

Try Xiangxiang Daily Now!

We Help You Launch New Products, And Continue To Grow. Try Us With 20% Off Your First Order!

Final Thoughts

These are the basic steps of cosmetic production. A detailed flowchart can provide more specifics.

Other factors affect product quality too. Clean facilities, high-quality water, and stable formulations help prevent contamination.

Table of Contents

Latest Blog Posts

Check out the latest industry trends and take inspiration from our updated blogs, giving you a fresh insight to help boost your business.